OEM Flooring Products | Bulk Orders, Private Labeling & Fast Global Delivery

Trusted OEM flooring supplier since 2006. 5M+ sqm annual capacity, SGS/CE-certified. Custom packaging, competitive MOQ. Download catalog & start your project!

PVC flooring definition and core advantages

PVC flooring (polyvinyl chloride flooring) is a new type of environmentally friendly flooring material made of polymer polyvinyl chloride resin, which is realized through multi-layer composite technology:

- Surface: UV coating (anti-scratch and wear-resistant)

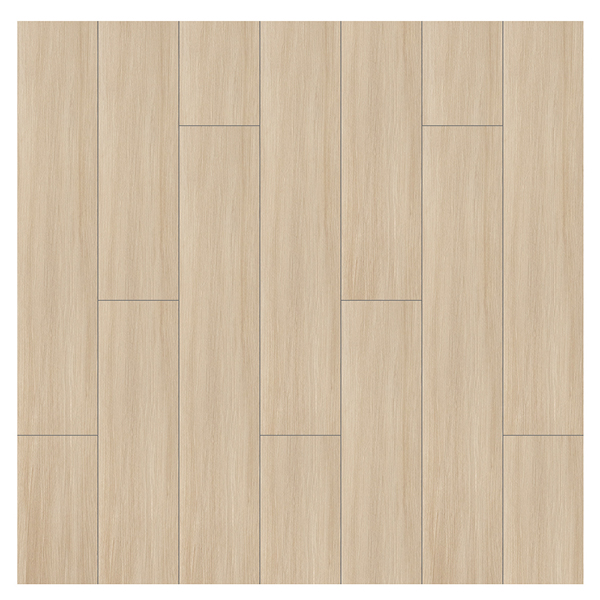

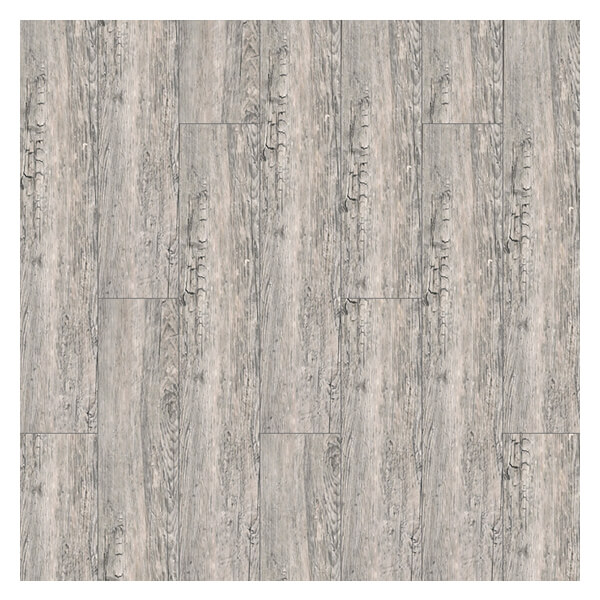

- Decorative layer: high-definition printing (wood grain/stone grain/creative patterns)

- Core layer: high-density PVC foam substrate (cushioning and mute)

- Bottom layer: cork/EVA padding (moisture-proof and heat preservation)

Commercial vs Residential

| Commercial PVC flooring | PVC flooring for domestic use | |

|---|---|---|

| Wear layer | 0.3-0.5mm(Class P) | ≥0.7mm(EN 660-2 Class T) |

| Fire Rating | EN13501-1 Bfl-s1 | EN13501-1 Efl |

| Thicknesses | 4.0-8.0mm | 1.0-3.0mm |

| Value-added service | 3D rendering | Free sample shipping + DIY video tutorials |

| Lead Time service | 15 days | 20 days |

Our pvc flooring options

At our BAOLIN PVC flooring factory, we provide homes and businesses with flooring solutions that combine beauty and resilience with easy installation and long-lasting performance.

What is PVC flooring?

PVC flooring (polyvinyl chloride flooring) is a new type of environmentally friendly floor decoration materials made of polyvinyl chloride resin as the main raw material.It achieves high simulation of wood grain, stone grain and other visual effects through multi-layer composite process (wear-resistant layer, decorative layer, base layer, backing layer), and at the same time, it has waterproof, wear-resistant, mute and other practical performance, which is widely used in family, commercial, medical and other scenes.

Excellent water and moisture resistance

✅Non-absorbent, non-expansion: the main material is hydrophobic resin, long-term soaking without deformation, suitable for bathrooms, kitchens, basements and other humid areas.

✅ Anti-mould and anti-bacterial: the surface is non-porous, eliminating the breeding of bacteria, in line with the needs of hospitals, laboratories and other high hygiene standards.

Environmental safety

✅Zero formaldehyde: Passed FloorScore®, SGS, CE and other international certifications, suitable for children’s room and elderly room.

✅Recyclable: Waste materials can be recycled, reducing the burden on the environment.

Super wear-resistant and durable

✅Wear-resistant layer thickness: commercial grade products up to 0.7mm, resistant to high-heeled shoes, trolleys and other long-term friction

✅Impact resistance: SPC (stone-plastic) locking floor can bear the weight of furniture movement, no indentation

Easy to install & easy to maintain

✅DIY friendly: support self-stick and lock splicing (no glue required), 100m2 space 1-2 days to complete.

✅Wipe clean: no need to wax, daily cleaning with a damp mop can restore as new.

PVC flooring vs traditional flooring

| Characterisation | PVC FLOORING | Wooden Floor | Tiles |

|---|---|---|---|

| Waterproof | Fully waterproof | Fear of water and easy to deform | Waterproof but seepage-prone seams |

| Abrasion Resistance | High (commercial grade up to 10+ years)) | Medium (requires regular maintenance) | High (but cold and hard surface) |

| Installation Cost | Low (DIYable) | High (professional paving required) | Medium (cement mortar required) |

| Environmental | Formaldehyde-Free | Solid wood is environmentally friendly, laminate contains glue | Environmentally friendly but high energy consumption for production |

How Are PVC Floors Installed?

Prepare a clean, dry, and level subfloor to install PVC flooring. Measure and plan the layout, then cut and trim the PVC planks to fit. Apply the recommended adhesive to the subfloor, lay the PVC flooring carefully, and use a roller to ensure good adhesion. Trim any excess material, install transition strips where needed, and finish with baseboards or molding for a polished look. A final inspection ensures a secure and professional installation.

PVC flooring is one of the most versatile flooring options on the market. From its water-resistant properties to its wide range of colors and designs, there are many reasons to choose PVC over other materials. Are you ready to upgrade your home or business with durable and stylish PVC flooring? BAOLIN Flooring experts can help!

The Fire-Resistant PVC Flooring for Safe Environments

What makes PVC flooring fire-resistant? The secret lies in its stone-plastic composite (SPC) core. The high-density limestone powder within the core significantly reduces combustibility, making it a safer choice for both residential and commercial spaces. Additionally, PVC flooring is treated with advanced flame retardants that enhance its ability to resist ignition and slow the spread of flames.

When tested under stringent industry standards, PVC flooring demonstrates exceptional fire resistance, typically achieving a Class B1 or Class A fire rating (depending on regional certifications). This ensures compliance with safety codes for use in homes, offices, schools, and public areas, providing critical protection in emergencies.

PVC flooring FAQs

Is PVC flooring waterproof?

Do I need a professional to install PVC flooring?

Is PVC flooring environmentally safe?

What scenarios are PVC flooring suitable for?

What are the advantages of PVC flooring over other flooring?

Location of our flooring factory address

If you are looking for support for your flooring project, we are here to serve you! We are available 24/7 for your convenience!

The PVC Floor Factory

No. 100, Xixin 15th Group, Zhangqing Village, Yangshe Town, Zhangjiagang City, Suzhou City, Jiangsu Province

Telephones:+8618021644292

Email:jffloor@pvcfl.com